Biogas is produced by the anaerobic digestion or fermentation of biodegradable materials such as manure, sewage, municipal waste, green waste, plant material, and crops. Biogas comprises primarily methane (CH4) and carbon dioxide (CO2) and may have small amounts of hydrogen sulphide (H2S), moisture and siloxanes.

It is a renewable energy source, like solar and wind energy. Furthermore, biogas can be produced from regionally available raw materials and recycled waste and is environmentally friendly and CO2 neutral.

The gases methane, hydrogen, and carbon monoxide (CO) can be combusted or oxidized with oxygen. This energy release allows biogas to be used as a fuel. Biogas can be used as a fuel in any country for any heating purpose, such as cooking. It can also be used in anaerobic digesters where it is typically used in a gas engine to convert the energy in the gas into electricity and heat. Biogas can be compressed, much like natural gas, and used to power motor vehicles. Biogas is a renewable fuel so it qualifies for renewable energy subsidies in some parts of the world. Biogas can also be cleaned and upgraded to natural gas standards when it becomes bio methane.

The environmental benefits of Biogas is immense. Methane has a greenhouse gas (GHG) factor 21 times greater than CO2. Capturing methane from any substrate (example- waste), which would otherwise be emitted to atmosphere, and utilizing it for other purposes will obviously reduce the GHG impact. Biogas energy is considered to be carbon neutral since carbon emitted by its combustion comes from organic matter that fixed the carbon from atmospheric CO2. Additionally utilising biogas will replace fossil fuels, a main contributor to GHG.

We, SLV Consultants, can offer Biogas consultancy services for setting up commercial BioCNG plants and Biogas for electricity production units. We are able to give complete consultancy including assisting in applying for SATAT initiative, MNRE subsidy and other statutory clearances.

Bio-Methanization

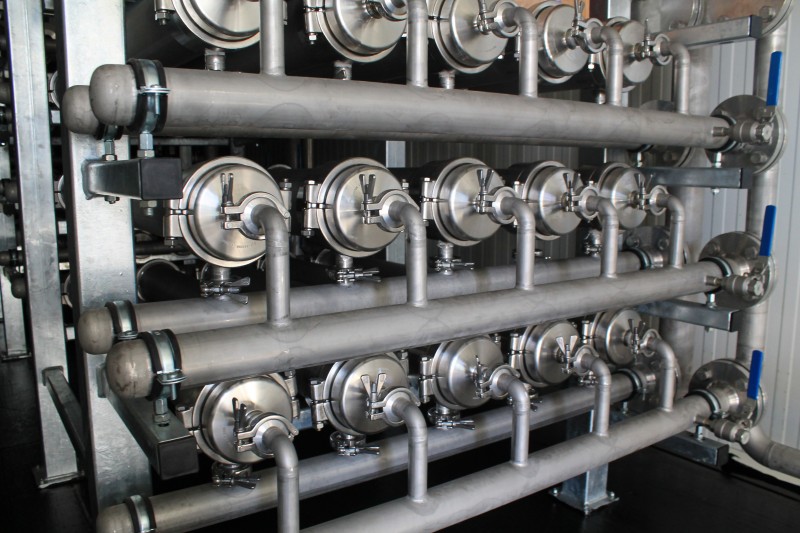

Biogas purification is a process wherein the methane in biogas is concentrated to natural gas standards. The system removes carbon dioxide, hydrogen sulphide, water and contaminants from the biogas. This purified biogas is also called biomethane or Bio-CNG (when compressed). It can be used interchangeably with natural gas.

Raw biogas produced from digestion is roughly 60% methane and 29% CO2 with trace elements of H2S; it is not high quality enough to be used as fuel gas for machinery. The corrosive nature of H2S alone is enough to destroy the internals of a plant.

Benefits of biogas purification is that the income can be augmented by upto 2-2.5 times when compared to direct electricity production from raw biogas. The uses of Bio-CNG is enormous. Chief users being:

- CNG based vehicles

- Restaurants

- Heavy industries using gas to cut metal

- Heavy boilers

- Ceramic industry

- Plastic production

- Fabric production

- Fertilizer production

- And much much more.

Contact Us

If you would be interested in knowing about the services offered by us regarding the businesses above, reach us now!